Lean Production Course

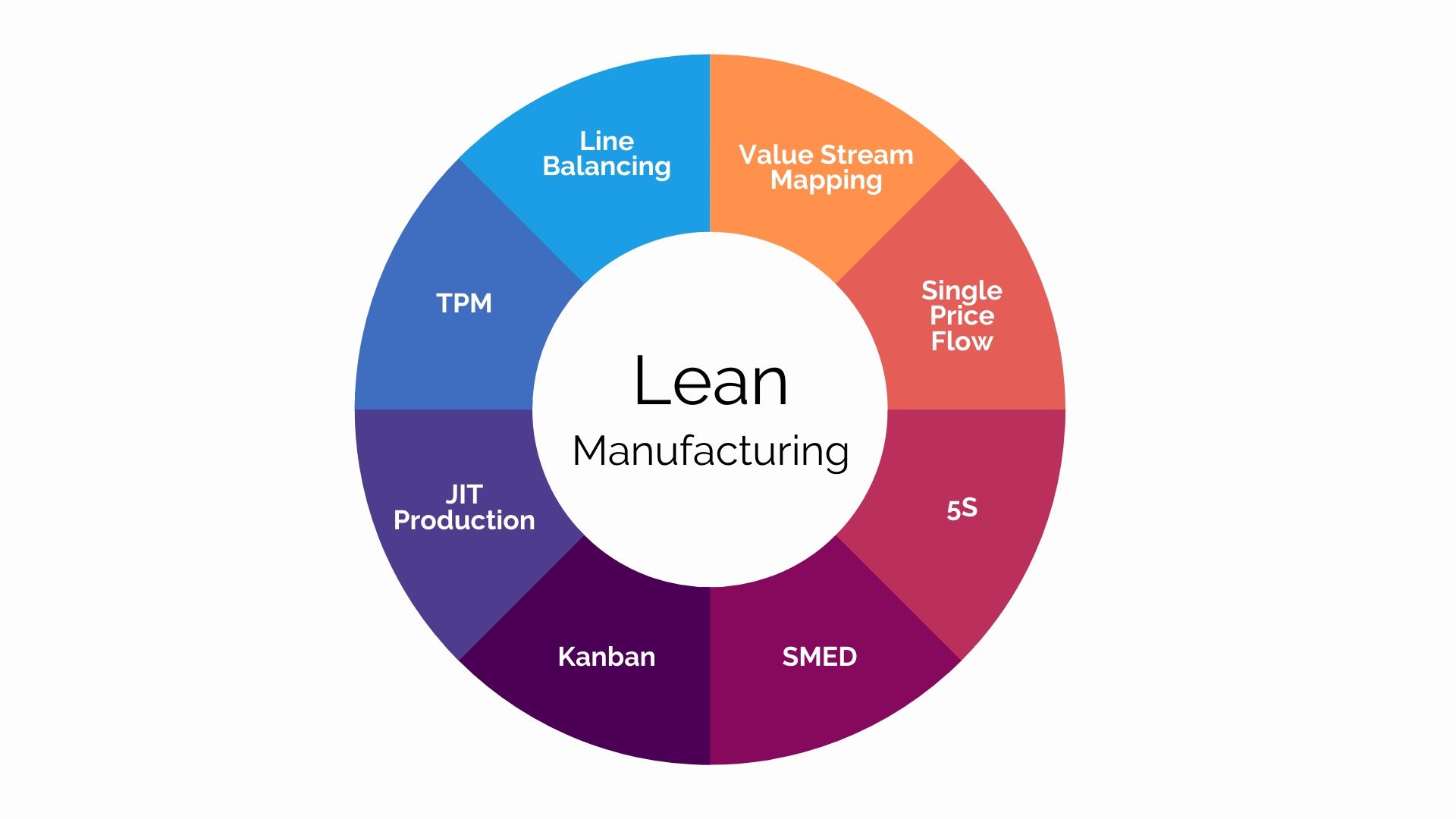

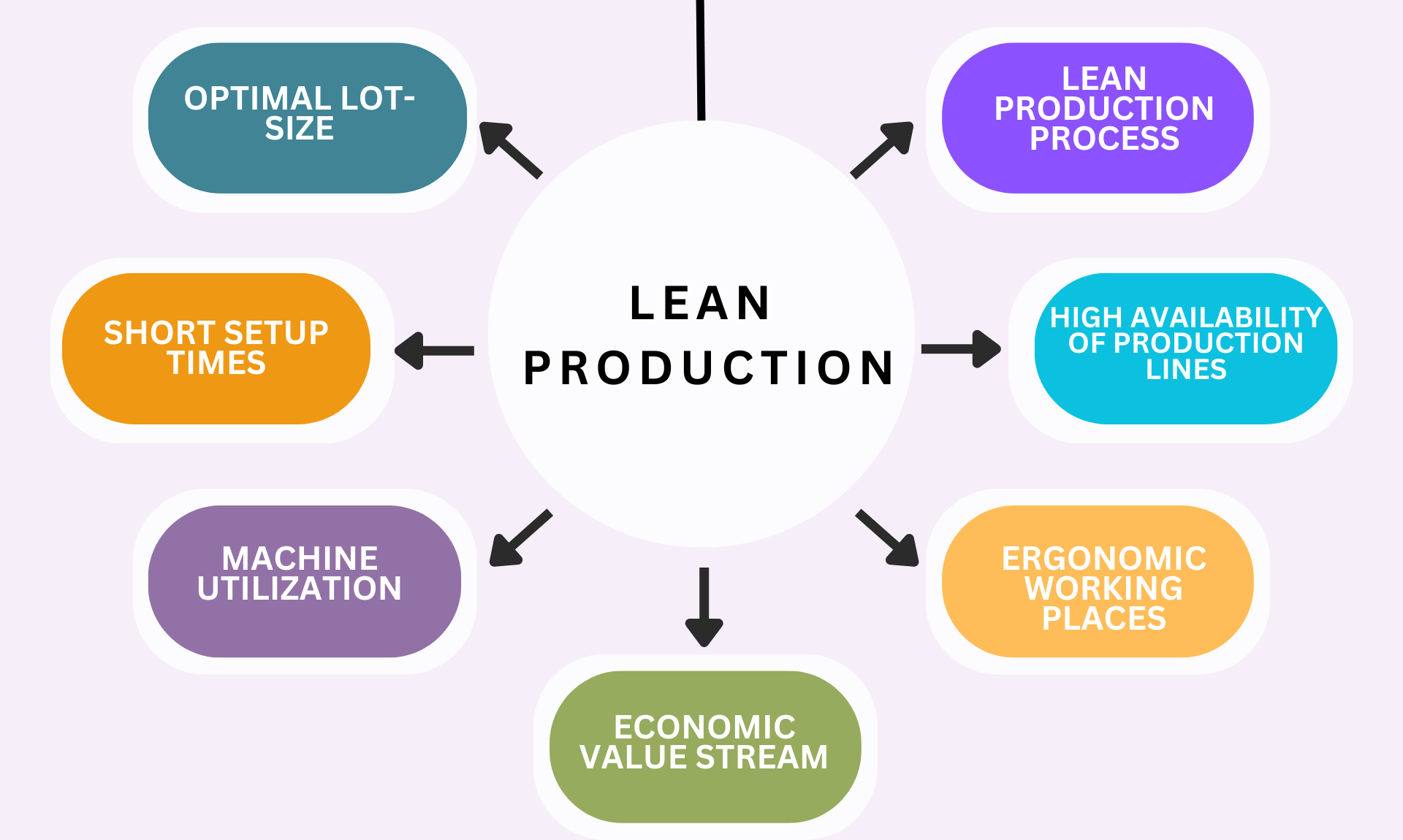

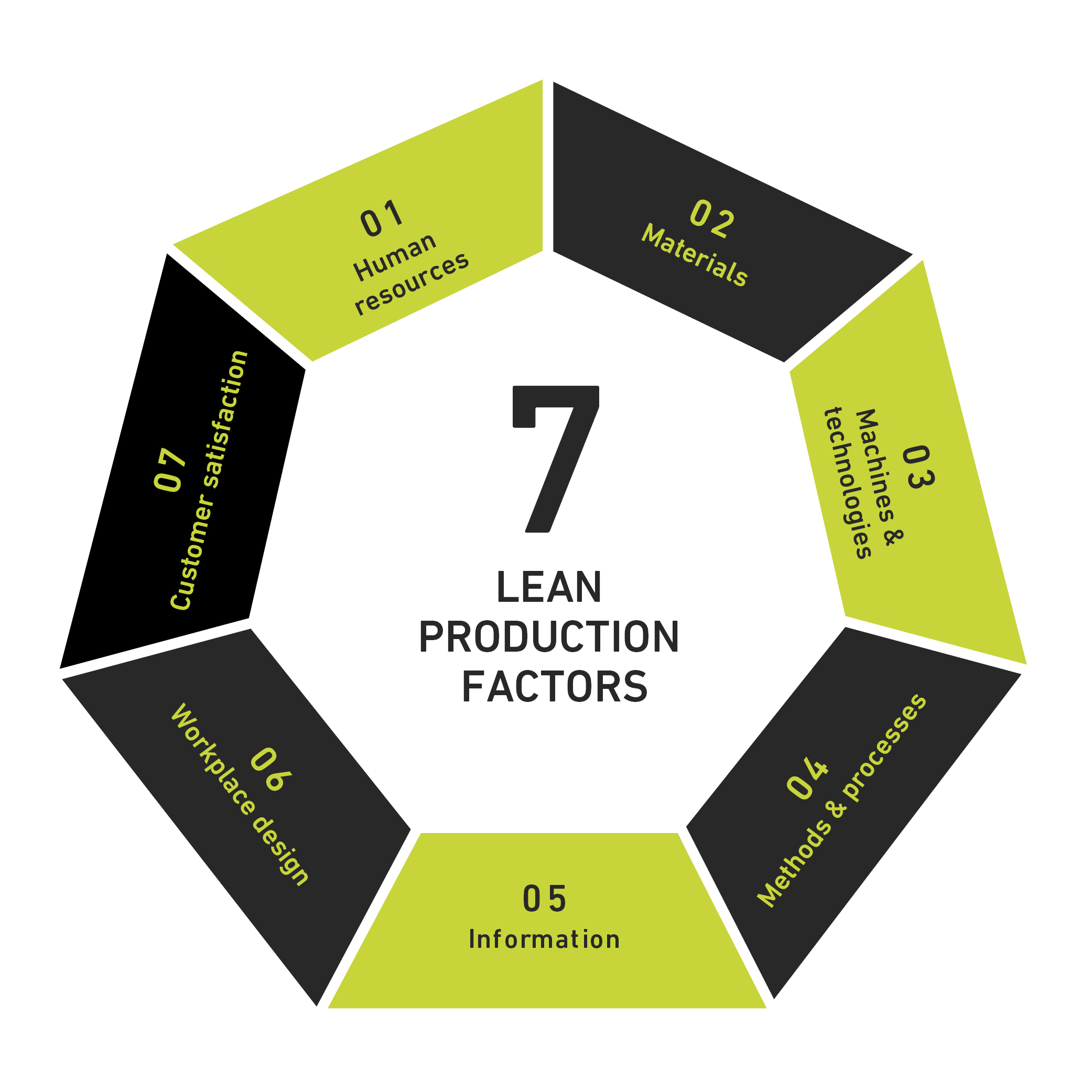

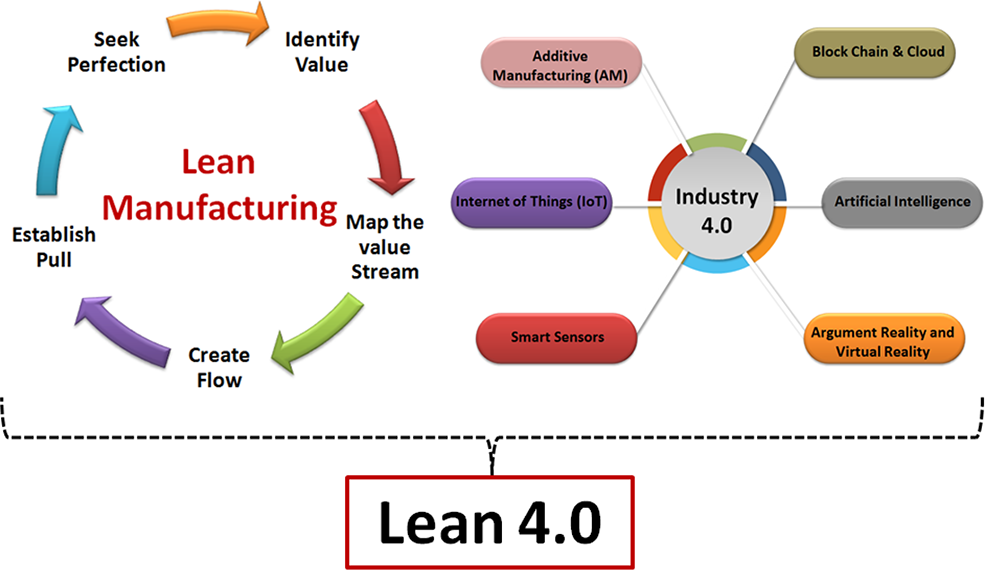

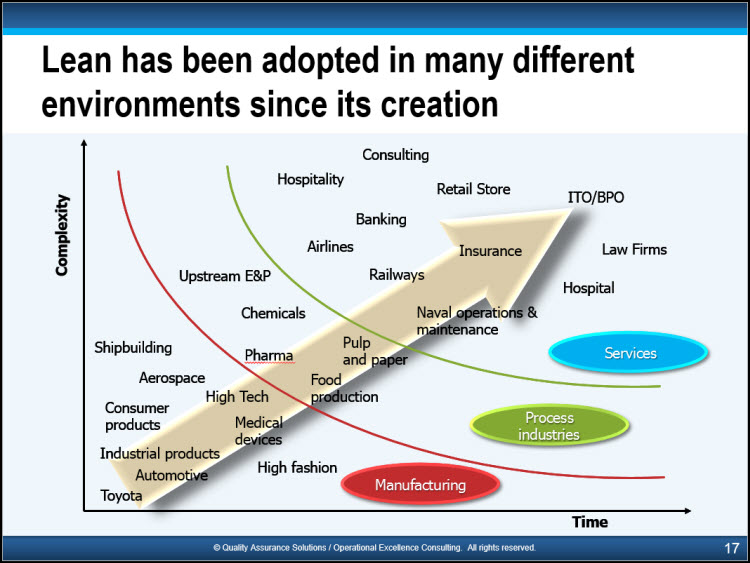

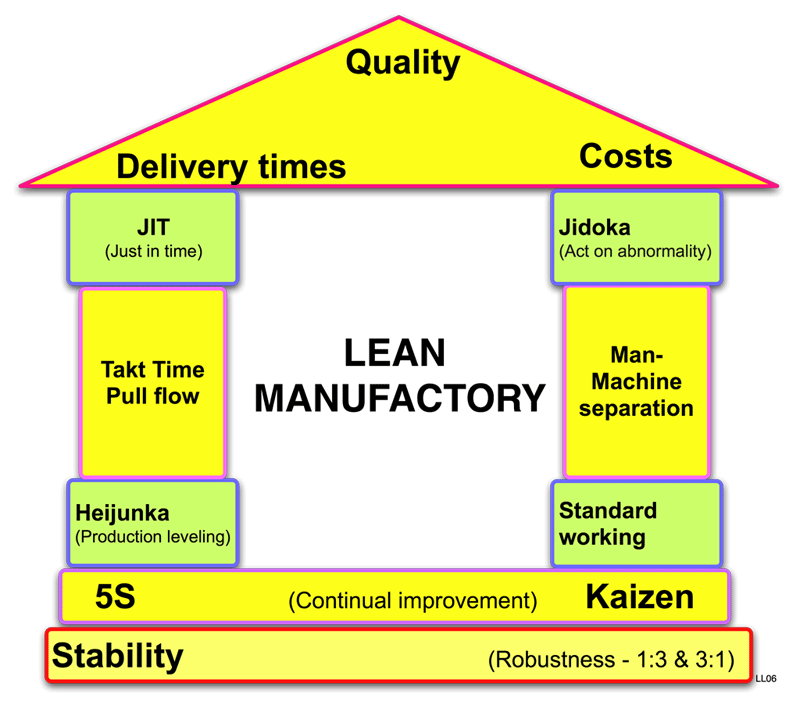

Lean Production Course - In this course, you will learn: Our lean manufacturing course curriculum includes: Lean certification at any of the three levels (bronze, silver or gold) offers individuals important benefits, including: In our lean management and lean manufacturing course, you will learn how to identify non value adding activities in a process. Explore integration of flexible manufacturing systems with lean principles, robotics, and automation. 5s is the first place many lean journeys start due to its quick and sustained impact on an organization. Lean manufacturing training provides the learner with lean implementation suggestions including approaches for addressing people issues, collecting and analyzing data to plan and track lean efforts, process workflow and layouts options with rationale and a sequential roadmap. Learn how to apply key elements of lean production, from minimizing inventory and reducing setup times, to using 5s and kaizen, in order to improve quality and productivity in your workplace. The lean practitioner certification empowers professionals to master lean principles and drive process improvements within their organization. Master the fundamentals of lean manufacturing, starting with its definition, history, and evolution. Lean manufacturing applies lean principles and practices, six sigma philosophy, and other tools to solve organizational challenges, reduce and eliminate waste and create a more efficient process, effectively reducing time, cost, and errors. Since then toyota has continued to practice and refine tps, and in the world outside toyota there has been an explosion of lean books, lean training, lean certification, and lean programs in most sectors of. And the model for lean production was not japanese automakers in general, but rather toyota and its toyota production system (tps). First pioneered by the toyota motor company in the 1930s, lean thinking quickly took hold and became a guiding principle for motorola and many other prominent companies. 5s is the first place many lean journeys start due to its quick and sustained impact on an organization. You will also learn how to eliminate these with very concrete lean tools and lean techniques. Our program requires that you gain knowledge by doing, driving a deeper understanding of the philosophy and methods of lean. Learn what lean is, why it matters, and how to lay the groundwork for a successful lean journey. Explore integration of flexible manufacturing systems with lean principles, robotics, and automation. This course will introduce participants to lean management, a methodology that aims to maximize efficiency and reduce costs in manufacturing environments. Our lean manufacturing course curriculum includes: Students will learn the concepts and tools of lean which include types of waste, visual management, 5s, value stream mapping, a3, & flow and how it applies to materials systems. Since then toyota has continued to practice and refine tps, and in the world outside toyota there has been an explosion of lean books,. In our lean management and lean manufacturing course, you will learn how to identify non value adding activities in a process. Lean management is a systematic approach that focuses on eliminating waste, optimizing processes, and. Master the fundamentals of lean manufacturing, starting with its definition, history, and evolution. Participants learn and develop an understanding of the critical concepts associated with. The course then delves into the eight types of waste, each thoroughly explained with its causes, effects, and elimination strategies. Lean manufacturing training provides the learner with lean implementation suggestions including approaches for addressing people issues, collecting and analyzing data to plan and track lean efforts, process workflow and layouts options with rationale and a sequential roadmap. Choose from a. Learn how to apply key elements of lean production, from minimizing inventory and reducing setup times, to using 5s and kaizen, in order to improve quality and productivity in your workplace. Purdue’s online lean principles course adds value to the program by giving learners a deep dive into lean practices and the ability to apply lean tools to current projects.. Choose from a wide range of lean courses offered by top universities and industry leaders tailored to various skill levels. You will also learn how to eliminate these with very concrete lean tools and lean techniques. The lean practitioner certification empowers professionals to master lean principles and drive process improvements within their organization. In our lean management and lean manufacturing. Upon completing this course, they will be able to apply the management principles of lean thinking and effectively utilize lean tools and principles to improve a value stream. Online lean courses offer a convenient and flexible way to enhance your knowledge or learn new lean skills. Lean management is a systematic approach that focuses on eliminating waste, optimizing processes, and.. Our 5s courses will have you implementing a 5s program in no time. This course will introduce participants to lean management, a methodology that aims to maximize efficiency and reduce costs in manufacturing environments. Choose from a wide range of lean courses offered by top universities and industry leaders tailored to various skill levels. Choose individual courses or complete the. First pioneered by the toyota motor company in the 1930s, lean thinking quickly took hold and became a guiding principle for motorola and many other prominent companies. With kaizen™ lean training, we guide change and certify expertise, providing certification that acknowledges the value of mastering adaptation and improvement. Master the fundamentals of lean manufacturing, starting with its definition, history, and. Purdue’s online lean principles course adds value to the program by giving learners a deep dive into lean practices and the ability to apply lean tools to current projects. Online lean courses offer a convenient and flexible way to enhance your knowledge or learn new lean skills. Explore integration of flexible manufacturing systems with lean principles, robotics, and automation. Lean. This course will introduce participants to lean management, a methodology that aims to maximize efficiency and reduce costs in manufacturing environments. Our 5s courses will have you implementing a 5s program in no time. Learn what lean is, why it matters, and how to lay the groundwork for a successful lean journey. Lean management is a systematic approach that focuses. Our 5s courses will have you implementing a 5s program in no time. Lean certification at any of the three levels (bronze, silver or gold) offers individuals important benefits, including: Lean manufacturing applies lean principles and practices, six sigma philosophy, and other tools to solve organizational challenges, reduce and eliminate waste and create a more efficient process, effectively reducing time, cost, and errors. Find course listings and member discounts at asq.org. This course will introduce participants to lean management, a methodology that aims to maximize efficiency and reduce costs in manufacturing environments. In our lean management and lean manufacturing course, you will learn how to identify non value adding activities in a process. Online lean courses offer a convenient and flexible way to enhance your knowledge or learn new lean skills. You will also learn how to eliminate these with very concrete lean tools and lean techniques. Master the fundamentals of lean manufacturing, starting with its definition, history, and evolution. Learn what lean is, why it matters, and how to lay the groundwork for a successful lean journey. Explore integration of flexible manufacturing systems with lean principles, robotics, and automation. Our program requires that you gain knowledge by doing, driving a deeper understanding of the philosophy and methods of lean. Purdue’s online lean principles course adds value to the program by giving learners a deep dive into lean practices and the ability to apply lean tools to current projects. The lean management fundamentals course is designed to provide participants with a comprehensive understanding of lean principles and practices. Our lean manufacturing course curriculum includes: 5s is the first place many lean journeys start due to its quick and sustained impact on an organization.Lean Manufacturing Training Materials Lean Factories

Best Lean Manufacturing Courses & Certificates Online [2024] Coursera

Lean Manufacturing Training Materials Lean Factories

Turnkey solutionsFactory Automation LEAN ON US

Lean Production Basics of methodical process optimization

Lean Manufacturing Discover the Principles and Objectives

Lean Manufacturing Lean Principles Lean 5S, 45 OFF

Streamlining Production How Lean Manufacturing Can Revolutionize Your

Lean Manufacturing Course atelieryuwa.ciao.jp

Lean Six Sigma Certification Course Deployment Of Lean Manufacturing

Lean Management Is A Systematic Approach That Focuses On Eliminating Waste, Optimizing Processes, And.

By Focusing On Customers' Needs, Lean Six Sigma Aims To Reduce Waste Across The Production Process And Continually Improve The Process Itself.

Upon Completing This Course, They Will Be Able To Apply The Management Principles Of Lean Thinking And Effectively Utilize Lean Tools And Principles To Improve A Value Stream.

Students Will Learn The Concepts And Tools Of Lean Which Include Types Of Waste, Visual Management, 5S, Value Stream Mapping, A3, & Flow And How It Applies To Materials Systems.

Related Post:

![Best Lean Manufacturing Courses & Certificates Online [2024] Coursera](https://d3njjcbhbojbot.cloudfront.net/api/utilities/v1/imageproxy/https://s3.amazonaws.com/coursera-course-photos/d6/5a3030a1ca11e7b74c7fa0c2763be9/Lean-Course-logo.png?auto=format%2Ccompress%2C enhance&dpr=3&w=265&h=216&fit=crop&q=50)